Master Planning and MEP Services

Creation of a master facility study and optimization plan is essential in guiding the long-term strategic development and implementation of upgrading, enhancing and maintaining your facility.

It is a dynamic, long-range planning document that provides a guide for your future growth and development.

Master Plans involve various components, including:

- Preliminary study

- facility, functional needs, spatial

- Conceptual design & order of magnitude estimates

- Identification of your priorities

- Establish energy efficiency measures

- Development of financial strategies

- Risk mitigation

- Develop a phasing plan & implementation schedule

- Strategies for energy efficiency

Master Layout

We expertise in project Master Layout for best land utilization. It includes M/C layout, electrical layout, fire safety plan, storage & handling provision, utility area, greenery, dockyard & parking provision etc. as per modern and standard operating procedure. Green field Factory – Warehouse execution & project management

- Project report preparation

- Land survey

- Factory/ warehouse master layout

- Machine layout

- Electrical layout

- Safety layout

- Storage & handling integration

- Civil design

- Technical supervision during execution

- Project handover

Green Field Plant setup with Machinery and Utilities

The success of setting up such a project is based on mainly following strategies for planning and implementation:

- Selection of Technology

- Selection of Equipment

- Project Monitoring

- Integrated Site Management

- Basic Design of All Department

- Accurate Cost Estimates and Realistic Project Budget

- Realistic Time Schedule

- Choice of Suitable type of Contract for the Construction Work

- Committed Contractors with Sufficient Capacity and Skilled Labour Force

Erection and Commissioning of Pipe Manufacturing, Pipe Coating and Steel Plants

Though start up and commissioning accounts for barely 5% of all operations, it’s during these types of non-routine activities that 70% of major accidents occur. When it comes to your operations, you’re the expert. But start up and commissioning isn’t part of your daily schedule. You may have to manage this effort only once every couple of years. Industries are focused on optimizing their operations, and personnel may not have the time or adequate experience with start-up and commissioning. The resulting loss of solid start up practices can lead to poor execution, which increases safety concerns, reduces post-start up reliability and leads to timeline delays. Every minute your team spends performing non-routine duties increases the likelihood of an accident. Every minute past your scheduled start-up date is money wasted and operational revenue lost. That’s why there’s Sure Start. Our 100+ commissioning and construction managers, technicians and electricians perform startups each year. We work in parallel with construction efforts and partner with your team to minimize downtime, enhance reliability and finish ahead of schedule. By drawing on the efficiencies gained, our 200,000+ hours of collective annual experience, our Proven process helps you startup smarter — and sooner.

Dealing into Steels, Pipes , Fittings, API 5CT and OCTG accessories, Pipe Connectors

- Oil and Gas Pipes and Tubes as per API 5L Specification

- Casing, Tubing and Conductor Piping

- Couplings, Connectors, Pup Joints, Cross Overs, Lifting Plugs

- Stainless Steel Seamless and Welded Tubes as per A 358, A 312

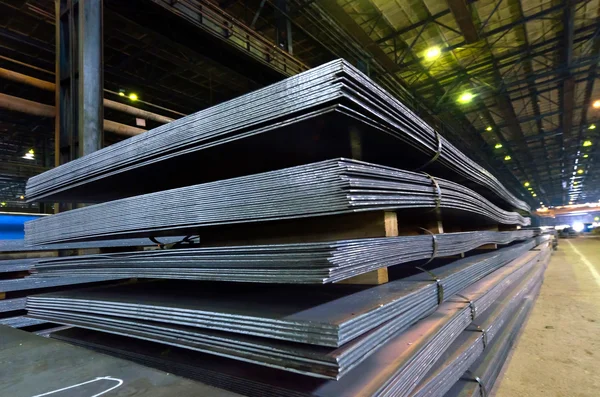

- Steel Plates for Pipe Manufacturing

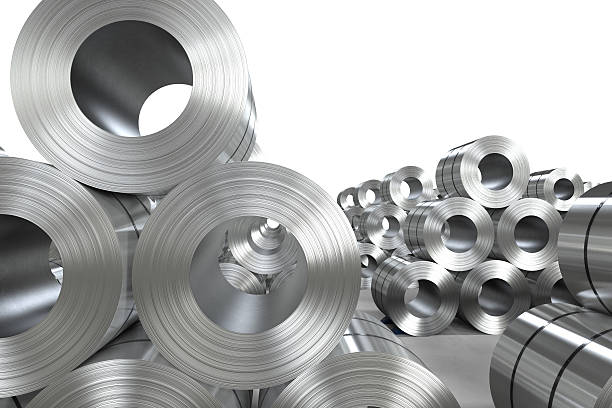

- Steel Coils

- Structural Steel

- Structural Hollow Section

Dealing into different Pipe Manufacturing and Steel Industries Related Machinery & Heavy Fabricated Equipments

We are committed to supply and deliver most Efficient and Modern state of art Technology Driven Pipe Manufacturing and Steel Industries Related machineries across the world. We can offer ERW Mill, L SAW Plant, H SAW Plant, Carbon Steel Seamless Plant, Stainless Steel Seamless and Welded Plant. Hot rolled Mill and Cold Roll Mill, Strip Processing Line, Induction Heater, Tooling. We have Technocrat and Experience Team and also have tie up with Machinery and Equipment Manufacturer across the Globe.

Trading of Old Plant & Machinery and Revamping of Old Equipment

We can offer the Old Plant and Machinery related to Pipe Manufacturing and Steel Industries.

- Technical Evaluation of Equipment / Plant with respect to Condition, Technology

- Right Valuation

- Right Time Delivery

- Revamping of Equipment / Replacement of Components

- Upgradation of Software and Electricals

Supply of Pipe Handling and Material Handling Equipments

Pipe Handling Equipment is equipment used for movement of the pipe while manufacturing in Plant. We offer wide range of Pipe Handling Equipment from Smaller to Large Capacity and customized solutions.

- Let Down

- Kick Out

- Bridge

- Conveyors

- Turning Rolls

- Anti-Roll Back Stop

- Blast Line and Coating Line Conveyors

- Pipe Transfer Carts

Material handling equipment (MHE) is mechanical equipment used for the movement, storage, control and protection of materials, goods and products throughout the process of manufacturing, distribution, consumption and disposal. The different types of handling equipment can be classified into four major categories: transport equipment, positioning equipment, unit load formation equipment, and storage equipment.

- Industrial Trucks

- Conveyors

- Cranes

- Lifts and Elevators

Industrial Automation and Strategic Industrial Solutions

- Process Automation

- Control System Design and Integration

- Productivity Improvements

- Energy Efficiency

- Automation Strategy

- Operation Technology

- Manufacturing Integration

- Work Process Management

- Performance Analytics

- Implementing methodology in production planning and control

- Rejection/defect analysis by SQC and reduction

- Factory/Office improvement implementation in terms of safety, 5S, FIFO, visual control

- Integration of Production- Stores- Material Handling

- Training in Industrial Safety , 5S & housekeeping , FIFO (First in first out), Quality awareness & compliance , Preventive maintenance , Production planning & control , Rejection analysis & reduction & Modern storage practice

PEB Design and RCC Design

- Provision of Structural Design (RCC and Steel design) drawings for residential, commercial and industrial buildings based on Architectural layout drawings.

- Design of Pile, Raft and Footing foundation for RCC and Steel Structures.

- Provision of Pre Engineered Building (PEB) design and drawings for large span steel structures.

- Provision of Design and Layout for Liquid retaining structures.

- Provision of design and drawings for Sewage Treatment Plants and structural drawings for execution.

- Provision of design and drawings for minor Bridges and Culverts.

- Provision of Detailed Design Report (DDR) to support drawing based on Client request.

- Vetting of structural drawing based on detailed design report.

- Proof checking of structural drawing to check for the mistakes and optimization of the drawings.

- Preparation of Conceptual Project Report (CPR), and Detailed Project Report (DPR).

- Provision of Pre-cast Structure design for Residential and Commercial buildings.

- Issue of Stability Certificates to all type of Buildings

Smart City Projects

As cities get smarter, they are becoming more livable and more responsive—and today we are seeing only a preview of what technology could eventually do in the urban environment. Until recently, city leaders thought of smart technologies primarily as tools for becoming more efficient behind the scenes. Now technology is being injected more directly into the lives of residents. Smartphones have become the keys to the city, putting instant information about transit, traffic, health services, safety alerts, and community news into millions of hands. After a decade of trial and error, municipal leaders are realizing that smart-city strategies start with people, not technology. “Smartness” is not just about installing digital interfaces in traditional infrastructure or streamlining city operations. It is also about using technology and data purposefully to make better decisions and deliver a better quality of life. Quality of life has many dimensions, from the air residents breathe to how safe they feel walking the streets. It finds that cities can use smart technologies to improve some key quality-of-life indicators by 10 to 30 percent—numbers that translate into lives saved, fewer crime incidents, shorter commutes, a reduced health burden, and carbon emissions averted.